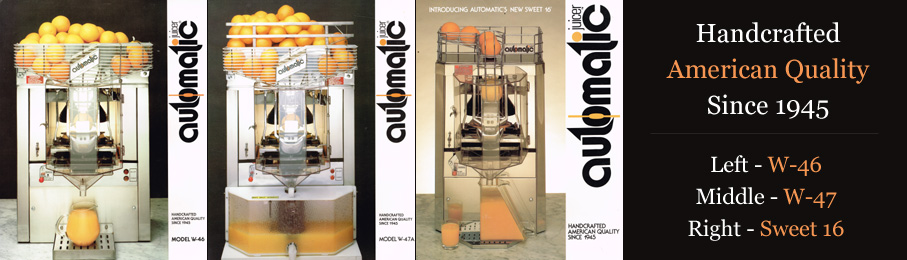

Automatic Juicer - How It Works!

Dozens of oranges are first loaded into a hopper on top of the machine. From there, they automatically gravity-feed onto a sloped wire ramp where they line up before a three-fingered index arm. At the start of the operation, the index arm releases the first orange so that it drops through a wire mesh runway into a waiting through. The index arm is permanently affixed to a cross arm inside that synchronizes the whole sequence.

![]()

After the orange drops through the wire mesh runway, it lands neatly centered before a vertical cutting blade. Two feeding shoes, attached to a U-shaped feeding arm, now push the orange against a sharp blade which divides the orange neatly into halfes. The feeding arm pivots on the top plate.

further inward pressure of the feeding arms gently guides the orange halves over wedge shaped dividers which direct the halves so that they seperate and fall, cut-face down onto a slotted rubber drain pad. Then the feeder arm and shoes return to their original position.

Two rubber pressure cups now descend over each orange half and apply sufficient pressure to squeeze out the juice. Cup pressure is regulated by a spring-loaded compenstor so that the peels are not crushed. The orange juice flows through a strainer at the bottom of the machine into a waitign receptacle. The pressure cups then move upward. Two flipper arms swing across the drain pad and push the now squeezed out orange halves into a discard bin. Total time elapsed per cycle is three seconds.